ABB arc welding robot IRB1410 body

ABB Robot IRB1410 Performance Parameters:

Load: 5 kg;

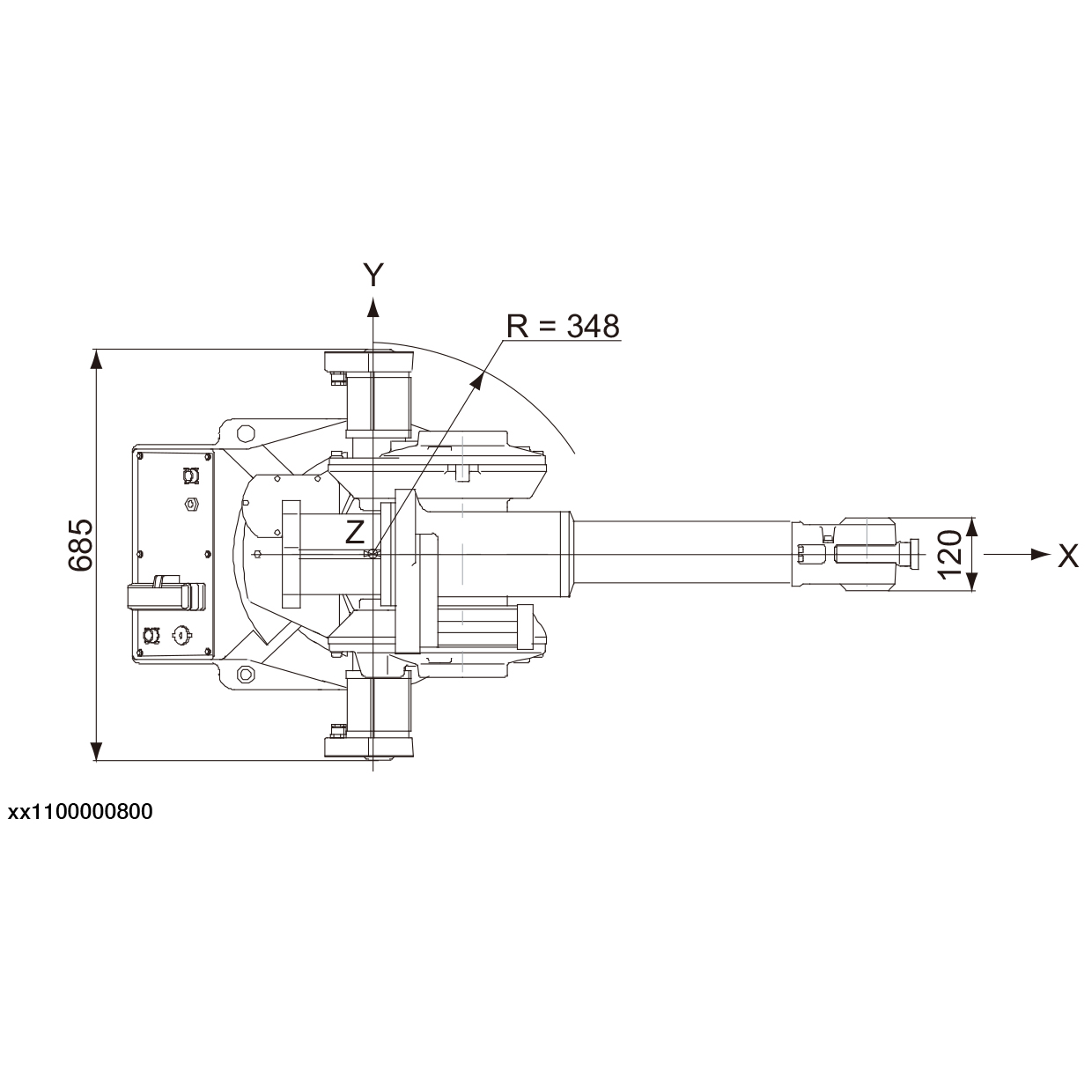

Additional load: 18 kg (3rd axis), 19 kg (1st axis);

Number of axes: 6;

Integrated signal source: 12 signals from the upper arm;

Integrated gas source: up to 8 bar for upper arm;

Repetitive positioning accuracy: 0.05mm (average value of ISO test);

TCP maximum speed: 2.1 m/s

Power supply voltage: 200-600V, 50/60Hz

Rated value of transformer: 4kVA/7.8kVA, with external shaft

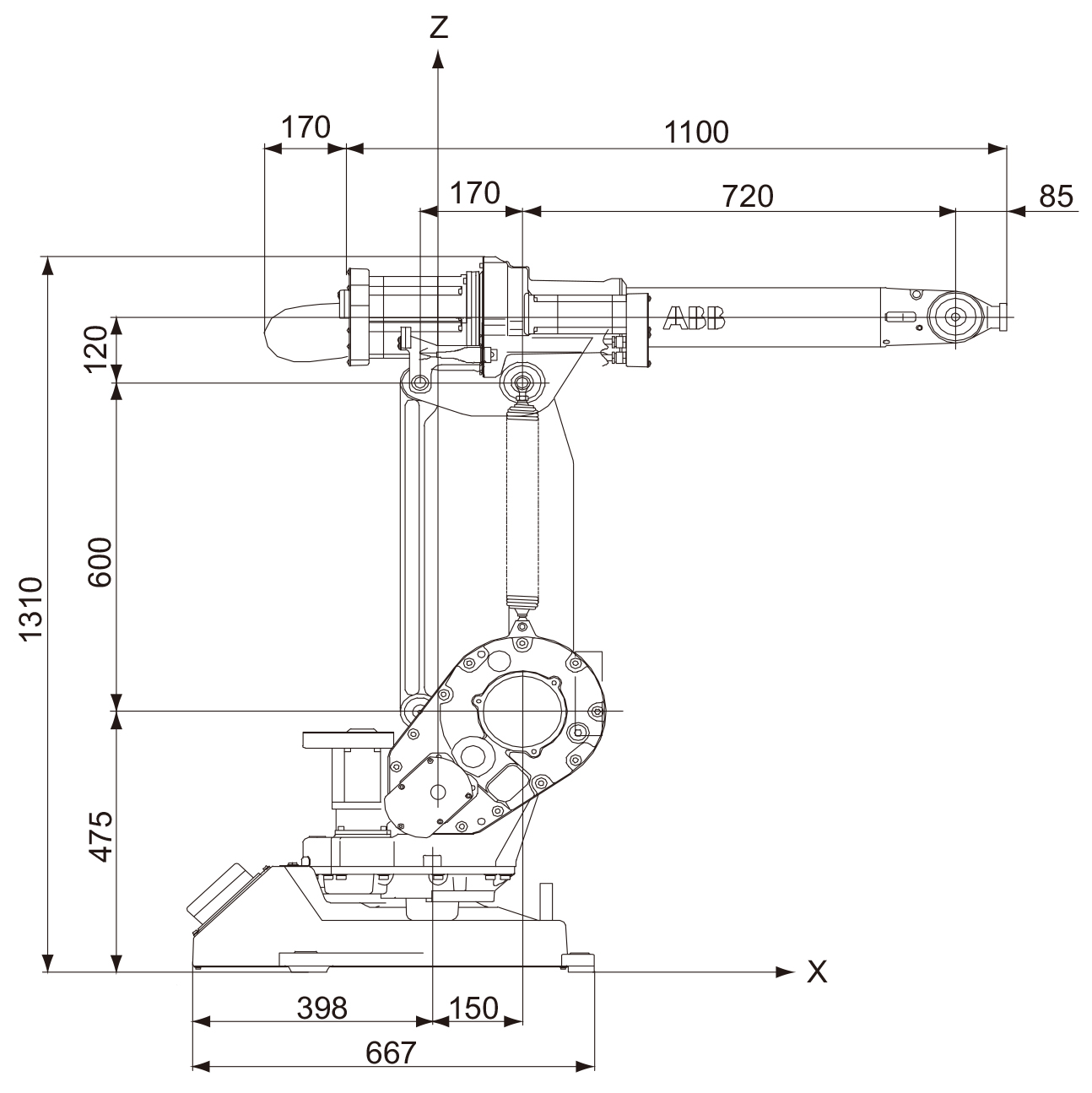

Robot base: 620 * 450 mm

Body weight: 225 kg

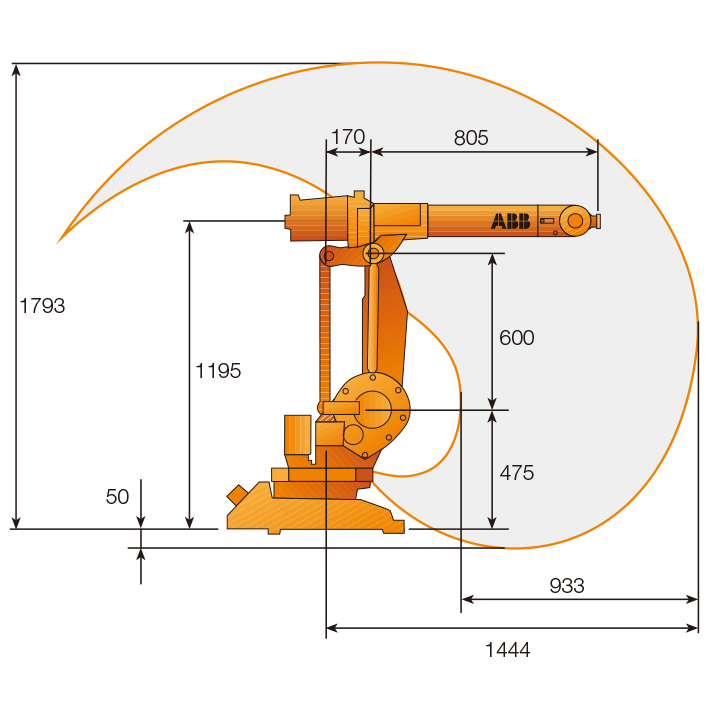

The ABB robot IRB1410 is specifically designed for arc welding, with wire feeding machine wiring installation holes to provide convenience for the robotic arm to carry process equipment. Summarized and tested in actual combat, optimized multiple times, arc IRB 1410 wrist load 5kg; The upper arm provides a unique 18kg additional load and can carry various process equipment. Exquisite control level and precision ensure perfect welding quality.

Traditional robots have an actual path that matches the programmed path at low speeds, but when making turning movements at high speeds, the actual path deviates from the programmed path. TrueMove, based on advanced feedforward servo control technology, greatly improves the accuracy of motion control and solves the problem of actual motion path deviation from the programmed path of robots at high speeds, truly achieving what is written is what is obtained.